Agents and Product Quality Validation in Bangladesh

Introduction: Why Quality Matters in Sourcing from Bangladesh

Bangladesh is globally recognized for its thriving textile and garment industry, growing electronics assembly capabilities, and an expanding light manufacturing sector. However, for international buyers and sourcing agents, product quality assurance remains one of the top concerns. Without boots on the ground, it’s difficult to ensure that production aligns with agreed specifications, certifications, or buyer expectations.

That’s where local agents step in—not just as facilitators, but as critical quality validation partners. In this blog, we explore how agents in Bangladesh play a key role in product inspection, compliance monitoring, and supplier accountability, helping foreign buyers mitigate risks and maintain product consistency.

🡪 Related reading: Sourcing from Bangladesh? Why a Local Agent is Crucial

Understanding the Risk of Poor Quality

For foreign buyers, receiving substandard products can have serious implications:

-

Damaged brand reputation

-

Returns and refund costs

-

Customs rejection or regulatory issues

-

Production delays

In industries like garments, leather goods, jute products, handicrafts, or consumer electronics, poor quality can result from:

-

Inferior raw materials

-

Non-compliance with specs

-

Unskilled labor

-

Inadequate factory testing

Agents act as the first line of defense against such issues.

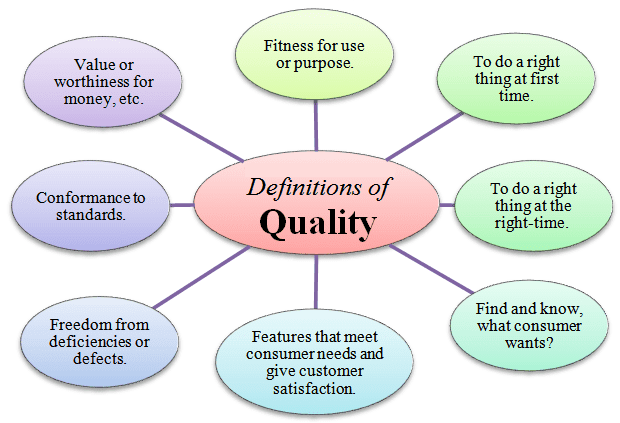

What Is Product Quality Validation?

Product quality validation is the process of ensuring that goods meet the agreed-upon specifications, industry standards, and buyer expectations before they are shipped. In Bangladesh, this may involve:

-

Factory audits

-

Raw material checks

-

In-line production inspections

-

Pre-shipment inspections (PSI)

-

Lab testing coordination

🡪 Related post: Top KPIs to Measure Agent Performance

How Agents Help Ensure Product Quality

1. Sourcing Only from Verified Factories

An experienced local agent knows which manufacturers have a track record of delivering quality and which ones cut corners. Agents often maintain a list of:

-

Certified suppliers (e.g., ISO, WRAP, GOTS)

-

Factories with ethical labor practices

-

Producers with modern machinery and QA systems

🡪 Also check: How to Draft a Service Contract with Bangladeshi Agents

2. On-Site Quality Inspections

Agents conduct in-person visits to ensure raw materials and production processes are up to standard. They may:

-

Check fabric GSM and dyeing consistency

-

Inspect stitching quality and measurements

-

Test product strength and durability

-

Review packaging and labeling for compliance

These inspections can occur at multiple stages, including during production and after completion (Pre-Shipment Inspections or PSI).

3. Third-Party Lab Testing Coordination

For certain categories like food, pharmaceuticals, or electrical products, third-party testing is necessary. Agents can coordinate tests with:

-

BSTI (Bangladesh Standards and Testing Institution)

-

SGS Bangladesh, Intertek, TÜV SÜD, etc.

They help in:

-

Sample collection and transport

-

Test report interpretation

-

Ensuring factory compliance with corrective actions

4. Language and Cultural Mediation

Miscommunication is a major quality killer. Agents bridge language gaps and cultural misunderstandings between foreign buyers and local manufacturers. They ensure that:

-

Technical specifications are clearly translated

-

Expectations are understood across departments (production, QA, shipping)

-

Cultural norms in communication and negotiation don’t result in misunderstandings

🡪 Related: Cultural Sensitivities Agents Handle on Your Behalf

5. Real-Time Updates and Reports

Modern agents in Bangladesh use tools like:

-

Video calls from the factory floor

-

Quality control checklists with photos

-

Regular WhatsApp/Email updates

-

Cloud-based inspection reports

This transparent communication keeps buyers in the loop and empowers quicker decision-making.

Industries Where Validation is Most Critical

While quality control is essential across sectors, it is particularly critical in:

| Industry | Common Quality Risks |

|---|---|

| Textiles/Garments | Color bleeding, shrinkage, poor stitching |

| Leather goods | Cracking, uneven tanning, odor |

| Electronics | Malfunction, poor soldering, overheating |

| Jute Products | Fiber inconsistency, weak structure |

| Home Decor | Paint chipping, sharp edges, non-durable materials |

🡪 See: Traditional Industries in Bangladesh That Are Going Global

Case Example: Apparel Buyer Avoids $50,000 Loss

A European clothing brand sourced 10,000 units of cotton t-shirts from Dhaka. Thanks to an agent’s mid-production visit, they discovered:

-

Stitching flaws in 25% of the batch

-

Discoloration in the dye due to fabric mismatch

The agent intervened, stopped further production, and had the materials replaced, saving the buyer from a potential $50,000 loss in product recalls and reputational damage.

🡪 Read: Case Study: How One Agent Boosted Exports by 30%

Working with Bangladesh-Agent.com

At Bangladesh-Agent.com, we provide end-to-end product quality validation services including:

-

Supplier sourcing and vetting

-

In-line and final inspections

-

Shipment QC verification

-

Lab testing coordination

Our team of experienced agents ensures your product meets global standards before it leaves Bangladeshi soil.

🡪 Contact us to get matched with a quality assurance agent or learn more about our sourcing and inspection packages.

Conclusion: Don’t Leave Product Quality to Chance

Product quality validation is not a luxury—it’s a necessity. With a local agent by your side in Bangladesh, you get eyes and ears on the ground, expert knowledge of local suppliers, and a proactive partner who ensures your goods meet market expectations Bangladesh-Agent.com.

In the competitive global marketplace, investing in quality assurance through a trusted agent is the key to long-term success.