Cross-Docking vs. Warehousing: Bangladesh-Specific Logistics Tips

As global supply chains evolve, efficiency has become the backbone of competitive logistics strategies. In Bangladesh—one of Asia’s fastest-growing sourcing destinations—choosing the right method between cross-docking and traditional warehousing can greatly influence cost, delivery speed, and client satisfaction. Whether you are a U.S. importer, a startup navigating Southeast Asia, or a multinational brand, making this decision in the Bangladeshi context requires localized insight.

Understanding how these two models function and how they align with Bangladesh’s infrastructure will help streamline your sourcing operations.

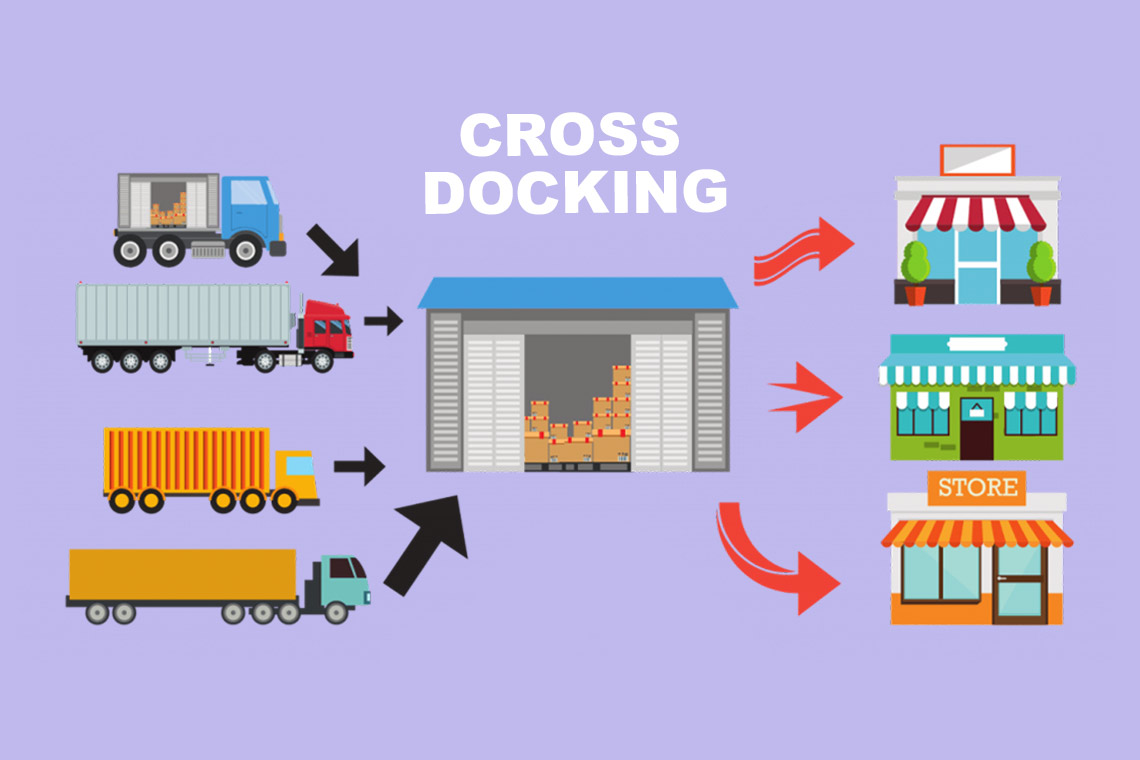

What Is Cross-Docking?

Cross-docking is a logistics strategy where inbound products are directly transferred to outbound transport with minimal or no storage time. The primary aim is to reduce inventory holding costs and shorten the delivery cycle.

In a Bangladesh setting, cross-docking is gaining attention, particularly in port-adjacent logistics zones near Chattogram and Dhaka EPZs. The rise of regional fulfillment centers makes this model increasingly viable.

Key Advantages of Cross-Docking in Bangladesh:

-

Lower storage costs due to minimal warehousing requirements.

-

Faster time-to-market for fast-moving goods like garments and accessories.

-

Improved product freshness for perishables, especially in food processing exports.

A trusted bestsourcing agent Bangladesh can coordinate direct shipment flow from the factory to port to final destination with minimum delays.

What Is Warehousing?

Warehousing involves storing products for short or long durations before final dispatch. It is the more traditional approach and remains dominant in sectors that deal with high-volume, seasonal, or variable-demand products.

Bangladesh’s warehousing infrastructure has expanded significantly, with growing investment in cold storage, bonded warehouses, and third-party logistics hubs in Gazipur and Savar.

Key Benefits of Warehousing:

-

Inventory buffering allows better preparedness for demand fluctuations.

-

Consolidation of goods from multiple factories before export.

-

Storage for quality inspections and labeling, especially for Western markets.

When longer lead times or regulatory checks are needed, partnering with a bestsourcing agent Asia enables better warehousing management and product readiness.

Cross-Docking vs. Warehousing: A Bangladesh-Specific Comparison

| Feature | Cross-Docking | Warehousing |

|---|---|---|

| Best for | High-velocity, low-complexity goods | Complex, regulated, or seasonal goods |

| Initial cost | Lower | Higher due to infrastructure and rent |

| Flexibility | Low—requires accurate timing | High—can accommodate changes and delays |

| Risk of damage | Lower (less handling) | Moderate (multiple touchpoints) |

| Lead time efficiency | Faster | Slower due to storage time |

| Suitability in Bangladesh | Excellent for apparel and FMCG exports | Ideal for electronics, pharmaceuticals, textiles |

How to Choose Based on Product Type

-

Garments & Textiles

Bangladesh is a leading exporter in RMG (Ready-Made Garments). Cross-docking works well when factory schedules align with shipping deadlines. -

Electronics or OEM Parts

These often need storage due to labeling, bundling, and documentation. Warehousing is more suitable. -

Food and Beverage

For products like frozen fish or mango pulp, cold storage warehousing and quick delivery via cross-docking may be combined.

A reliable bestsourcing agent Bangladesh can assess your SKUs and delivery schedules to determine the most efficient model.

Regulatory and Infrastructure Factors to Consider

-

Bonded Warehousing Regulations

Bangladesh offers bonded warehouses for export-oriented businesses. Working with a bestsourcing agent Asia ensures compliance with customs and tax laws. -

Port Efficiency

Chattogram port’s congestion can affect timing for both cross-docking and warehousing. Advanced coordination is essential. -

Road and Rail Access

Some warehouses in Dhaka and Narayanganj are better connected by road but limited in space for cross-docking. Selecting logistics parks with intermodal facilities is crucial.

Case Example: U.S. Retailer in the Apparel Industry

A U.S.-based retailer sourcing garments from Bangladesh faced rising storage costs due to inventory overflow. By shifting to a cross-docking model facilitated by their local bestsourcing agent Bangladesh, they reduced delivery time by five days and cut costs by 18%. The agent ensured goods moved from factory to the container yard within hours of quality inspection.

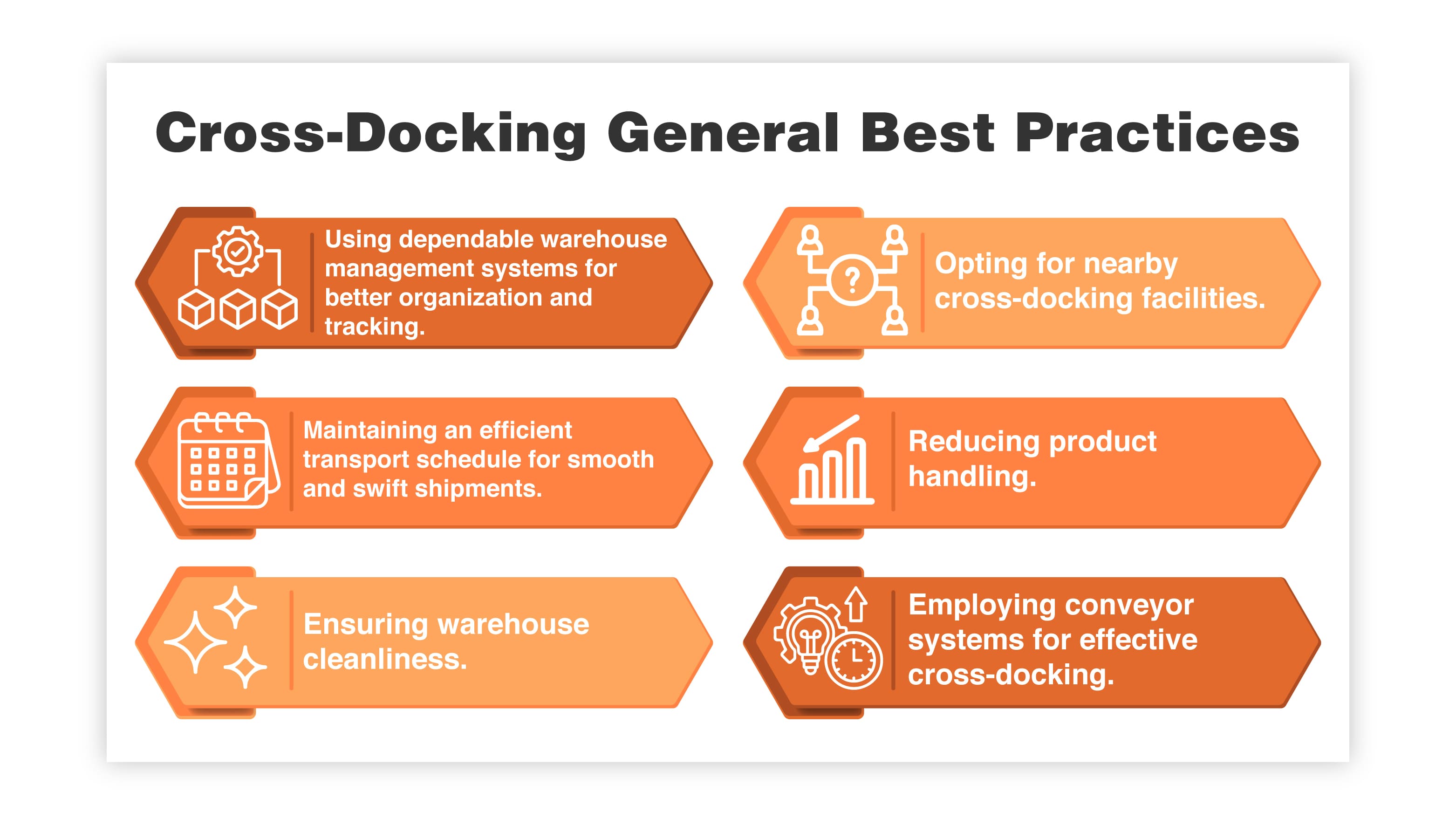

Practical Tips to Optimize Either Model

For Cross-Docking:

-

Sync factory production with vessel departure schedules.

-

Use RFID and barcode tracking to minimize manual handling.

-

Appoint a sourcing agent who can coordinate live freight movement.

For Warehousing:

-

Forecast demand to prevent overstock.

-

Consider hybrid models: short-term warehousing followed by just-in-time dispatch.

-

Invest in warehouse management systems (WMS) or work with agents who use them.

Conclusion

In Bangladesh’s rapidly maturing logistics landscape, both cross-docking and warehousing have vital roles. The best model depends on your product category, market expectations, and shipping timeline. With a well-informed sourcing strategy supported by a professional bestsourcing agent Asia, importers can cut costs, improve responsiveness, and better serve their global markets.

By aligning your logistics model with local realities, you’ll ensure smoother, smarter sourcing in Bangladesh’s competitive export economy.